Newbie 3D Printing

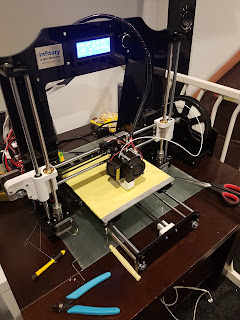

So I got my first 3D printer. It is an Infitary M508 from aliexpress.With little to no experience wasn't sure what I was looking for...

**BTW for later the filament for this unit is 1.75mm and Nozzle head is 0.3mm

It arrived relatively quickly and as a kit. When they say a kit they mean a kit:)

When you open the box you will see the 5 step motors (2 for Z-axis, 1 for Y-Axis, 1 for X-Axis and an extruder step motor), along with a circuit board (Arduino board custom made for 3d printers), power supply, LCD and SD slot and frame.

They also put all the videos and firmware for you on an SD card which is a nice touch. No manuals are printed out anywhere though.

Spent half the day peeling the brown tape from the frame and then followed the youtube videos to put it together. Overall there are a few complex pieces and making sure you are always on the correct side of the project is pretty important! put a few things the wrong way around, only to find later, for example, that I put the main Y axis screws in backwards *doh*.

The Y-Axis belt required a bit of time as you need small hands and a second pair of hands if available.

The X-Axis was even more painful, but I got through it.

Power was pretty straight forward, and I can't say it was to complicated. Just had to use a lot of zip ties to tidy up the cables. (you will need to buy quite a few small ones)

After putting together the cables, I highly recommend not following the video directions for the extruder cables they should go to the side not over the top, but if you aren't certain just follow the video. You will see what I mean later:)

Once it was assembled and I powered it on, it all seems to work with no smoke. That was a good sign. You can move the axis from the menu (Firmware is already installed on the Arduino - firmware is called Marlin, that's for a different day).

Could move the X axis and Y axis fine, but Z was making a grinding noise and getting stuck more often then not.

After loosening one side of the Z-Axis long screw shaft from the motor the Z axis moved freely on only one step motor. It would appear that the Z-axis screw wasn't fully aligned with the motor and with the X-Axis mount, there is no way to make it align better (as far as I can see), so I released a few screws (specifically the ones on the brass Z-axis to X-axis carriage which have the Z-axis shaft run through it) to give it the space it needs to move freely.

Alignment of the nozzle and the heating bed seemed rather simple just moved the Z axis limiter switch and twist the Z-axis to get the right height till they seemed to touch.

(limiter switch is the little switch which tells the arduino when you get to the minimum point, so it doesn't grind the motors)

After fixing that problem I tried loading filament. There is an easy way to do this.

1. Cut the filament with the cutter so that it is sharp on one end.

2. Providing you are using PLA, under the prepare menu goto preheat PLA, this will warm up the Nozzle to 190degrees.

3. Once it reaches 190, go back to the prepare menu and press change filament.

4. It will then try to retract the previous filament (which doesnt exist), wait a couple of seconds to let it go through its unloading cycle.

5. The put the filament in the small hole on the extruder stepper and press the round button. It should start loading the filament:)

Took me a while to figure out how to load it...

Okay so first a couple of pointers for newbies;

1. 3D printers print gcode files which are just machine instruction sets for vectors and movements (including commands for heating elements etc....)

2. You will need to install something like cuda on you PC to convert STL files which are exports from CAD type software to something your printer can understand. This is provided on the SD card with this unit (It can also be downloaded from the web)

3. The SD card has some gcode files on it already ready to test, so just insert that to test it.

So attempt 1 to print... First of DON'T DO THIS!

I didn't put down any tape (the yellow stuff in the picture above) because i didn't understand why I needed it (will explain later). I then proceeded to print the first file by selecting it from the menu on the SD card.

The bed warmed up, then the nozzle warmed up. (They do this so the nozzle doesn't start oozing while you wait for the heated bed)

The bed was not level, which means the nozzle nicely dug a long groove into my heated plate. quickly pulled the plug and read up on levelling.

So this is one thing I would probably make sure I had as a feature when I bought a 3d printer. The M508 does not come with auto levelling built in.

Levelling includes disabling you step motors (in the menu), taking a sheet of A4 paper and moving your nozzle across 4 different points of the bed to make sure it is barely touching the paper, by rotating the screws in the correct location. (there are other more scientific ways to do this, but this is simple enough for most).

Attempt 2... okay so I tried levelling... but didn't use the method with an A4, rather I tried eye balling it.

It started and didn't scrape the surface that was good, and then it started to print, but the filament just kept on being pushed around by the nozzle and detaching from the bed... stopped that and read more...

After reading more learned that a technic to make sure things stuck to the bed was to use painters tape (they yellow tape), so stuck that on and went on attempt 3.

Once again it started up but the same thing happened... the filament just detached from the bed!!!

Played with levelling for a good 2 hours, cause I didn't know what good looked like. Finally got to the point where it was slightly squishing the filament on the bed and it started to print properly. (A4 sort of worked:))

*Your gut feel will tell you that the head has got loose filament hanging from the heating process that is pushing the filament off the bed. That isn't the problem your bed is just of range. Do the levelling. It can also be a temperature issue but start with that one first.

BTW, if you haven't bought a printer, don't expect it to printing anything in a hurry. It takes hours!

After less than a couple of hours, my kids wanted me to print something for them, so I went over to thingiverse and found a Pitbull. I tried shrinking it on cuda (by changing the scale - so it wouldn't take so long). Generated the gcode and put it to print.

It started printing just fine, until the hind legs would just detach from the base mid print (even with the levelling done and the tape). I thought I was doing something wrong!! tried glue sticks, tried re-levelling, nothing worked. the legs kept coming off!!

What I quickly learned was that the surface area of the leg was just way to small for it to stick properly. I modified the STL using blender and put a bigger footing around it and it worked just fine.

So that's all from me today. If you got this far you are at the beginning of the journey:)

No comments:

Post a Comment